Sparks flying, engines humming, drills whirring—that’s the scene inside Fremont High School’s new Career and Technical Education (CTE) Center. You won’t see kids fiddling on phones or daydreaming at desks here. The center’s six labs are abuzz with sound and alive with activity all day as students weld, build, and design.

The CTE center opened this fall, part of a multiyear effort to reconfigure the school to train more students for great-paying careers in the trades. “We have to change the narrative because kids and their parents are used to hearing that you must have a four-year degree,” said Mark Shepard, Superintendent for Fremont Public Schools (FPS). “There are some great opportunities that don’t require a four-year degree.”

To promote its programming, Fremont’s CTE facility has been designed for maximum visibility. “There’s a lot of glass allowing views into the classroom from the outside and from the hallways,” said Shepard. “We know that if we’re going to expose students to these programs, they have to be able to see what’s going on in the labs.” Parents coming to events in the school’s gymnasium are also routed through the CTE center, where they can see robots, high-tech machinery, and projects in progress.

A Template for Success

The vision for the new CTE facility arose from the success of the high school’s welding program. That program began nine years ago as a partnership between the high school, Metro Community College (MCC), and Valmont. Todd Hansen, FPS Board of Education member and MCC Associate Vice-President, served an integral role in helping pull the program together. In recent years, Fremont High School has graduated 25-28 welders annually, providing local industry with a critically needed infusion of talent. The school’s welding grads have gone on to work for area manufacturers such as Valmont (Valley), Rosenbauer (Fremont), Smeal (Snyder), Lozier (Omaha), and Gnuse (Arlington). Meanwhile, MCC has used the welding lab to educate college students on nights, weekends, and in the summer—when the high school isn’t having classes. Additionally, local businesses have been able to send employees to the welding lab for job skills training. “If we can do this in welding,” Shepard said, “we can do it in other areas.” That attitude motivated the initiative to build the brand-new CTE Center to train students for multiple career tracks.

Doing the Homework

Fremont High School’s CTE facility was planned strategically, drawing on input from local businesses as well as research into other school buildings. FPS spent considerable time with the chamber of commerce and Greater Fremont Development Council (GFDC), meeting with every major industry in the community and surrounding areas. “We had good conversations with industry about their needs and what something like this could do to support them,” said Shepard.

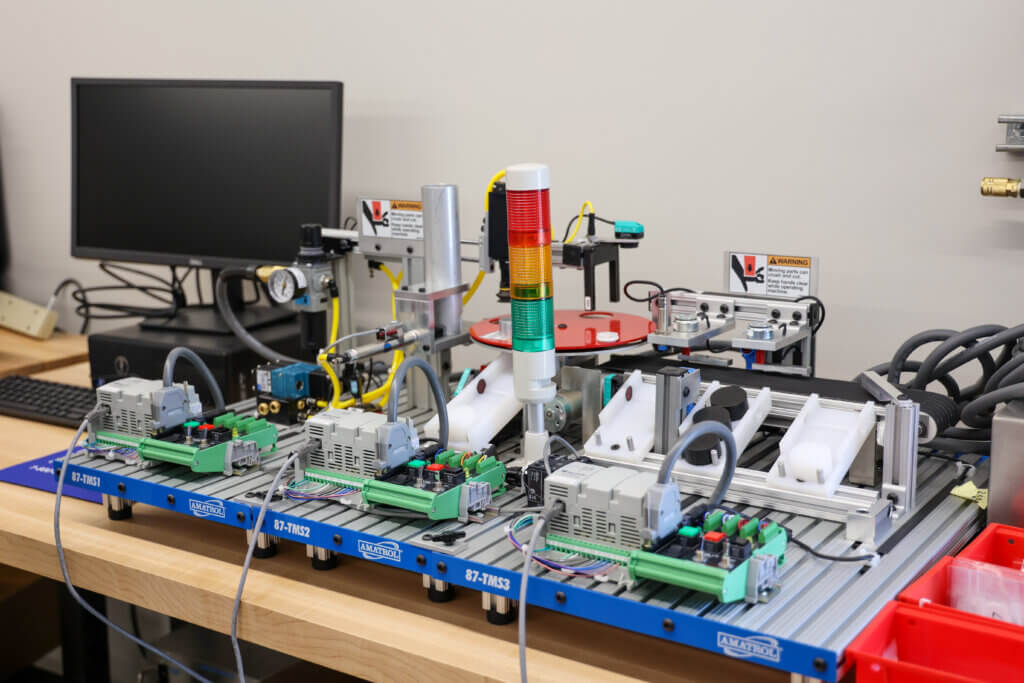

“FPS deserves a lot of credit for engaging area businesses,” said Megan Skiles, President & CEO of GFDC. “They’ve been eager to talk about the vision for the CTE facility, collect input on industry needs, and make sure the facility is industry-relevant.” In particular, the school consulted local businesses about their needs for high-wage, high-skill, and high-demand jobs. Through these conversations, FPS identified seven career pathways that could be accommodated in six labs: welding, auto tech and diesel tech (two pathways in a single lab), construction tech, health sciences, computer-aided design, and mechatronics.

The school also took groups of industry leaders to tour CTE facilities in Columbus, Grand Island, Fairfield (Sandy Creek Schools), Lincoln (Lincoln Public Schools at Southeast Community College), and Omaha (MCC’s South Omaha and Fort Omaha campuses). Seeing these educational centers helped inform FPS in its design decisions.

While constructing the CTE facility, the school revamped its curriculum to ensure students would have the requisite knowledge to begin work in the labs upon their completion. Teachers had to learn new skills and adjust to a different model of instruction. That was certainly the case for Keith Cunnings, who has taught industrial technology at the school for 24 years. He now teaches mechatronics and computer-aided design in the new labs, where he has access to the latest technology. “Keith is truly the epitome of retooling,” said Shepard. “He didn’t learn any of this [new technology] in class; he learned it all this last summer and this fall.” “I had 1963 machines, and I now I have this!” Cunnings marveled, describing how he’s been reading through manuals and rapidly learning new programming. “The trick is to stay one day ahead of the kids,” said Shepard, acknowledging that some students may eventually outpace their teachers in making use of the new technologies.

Generous Supporters

Construction of the $9.5-million facility is being financed by the community through a bond issue. “We’ve been a low-unemployment state for a number of years now, so this is a need that is easy for the community to rally around,” said Skiles. To equip the center, GFDC successfully applied for two Developing Youth Talent Initiative grants from the Nebraska Department of Economic Development. One award has helped furnish the CTE facility with equipment. The other award has enabled FPS to develop programming for middle school students so that they can work with small engines and learn to weld. “Starting earlier gives students exposure to some of the career opportunities that are out there, and it allows them to plan their high school experience,” Shepard said.

Area businesses have contributed more than $2 million—through both cash and in-kind donations—to the CTE center’s sustainability fund. This fund ensures that the facility’s operating costs are covered. Additionally, it will allow FPS to upgrade equipment in the facility so that students in the labs continually have access to the best, most technologically advanced training tools. Christensen Lumber, Fremont Beef Company, J. Skinner Bakeries, Lincoln Premium Poultry, Lozier Corporation, and Structural Component Systems are among the manufacturers who’ve invested in the CTE sustainability fund. All four local car dealerships are engaged in the automotive program. Each is providing vehicles for students to work on, along with cash donations toward tools. Methodist Fremont Health and Nye Health Services have generously contributed to the nursing lab to train future healthcare professionals.

“People will say, ‘Mark, you generated over $2 million in five weeks. That must have taken a lot of arm twisting!’ There wasn’t any arm twisting at all,” said Shepard. “Our community paid for the facility with the bond issue. FPS and MCC leveraged federal funds and grant dollars to equip it. The sustainability is now on local industry. They’re going to benefit from it, and they’ve stepped up in a big way to fund it.”

The Power of Partnership

When asked how he would advise other communities to enhance their CTE education, Superintendent Shepard emphasized collaboration. “The first and most important thing is to take the time to listen [to your industry partners],” he said. “The other advice I’d give is to work closely with your community college.”

Metro Community College has been a strong partner in the CTE project from the beginning. They’ve provided FPS with grant opportunities that the high school wouldn’t have had access to on its own. They’ve worked alongside FPS to ensure students can take dual-credit programming across all seven career pathways. MCC has also provided FPS with instructors in areas where the high school doesn’t have a specialist on staff. “For example, in automotive or diesel tech, you have to have an ASE certified mechanic,” Shepard explains. “We don’t have one on staff, but MCC is able to provide that for us. The same is true of our Certified Nursing Assistant program, where you have to have a trained individual who is an RN delivering the curriculum.”

Rave Reviews

Fremont students have jumped at the chance to learn in the new CTE facility. “We went from having 250 students in our CTE programs [previously] to having 450 participate this fall,” Shepard reported. “We’ll have 700 of our 1,700 students enrolled in programming this academic year in the new CTE center. The feedback has been all positive!”

Given Fremont’s strong manufacturing base, the CTE center is especially valuable for that industry. “In Dodge County, there are over 4,000 people working in manufacturing out of a total population of around 36,000,” Skiles said. “That’s a very significant chunk of our workforce. The concentration of manufacturing in Fremont is about 2.9 times greater than the national average. We are a manufacturing community, and over the past few years we’ve seen manufacturing jobs grow even more attractive in terms of benefits and opportunities for advancement.”

As Nebraska celebrates Manufacturing Month, Fremont’s investment into career and technical education sets a great example of what’s possible when a community collaborates on workforce development. For pictures of the new CTE center, see the attachments or go to this photo album.